According to SPER Market Research, the Global Metallic Glasses Market is estimated to reach USD 3.46 billion by 2034 with a CAGR of 6.76%.

Introduction and Overview

The report includes an in-depth analysis of the Global Metallic Glasses Market, including market size and trends, product mix, Applications, and supplier analysis.

The global Metallic Glasses market was valued at USD 1.8 billion in 2024, and it is expected to rise at an 6.76% CAGR from 2025 to 2034. The rising demand for high-strength and lightweight materials, excellent magnetic and corrosion-resistant properties, growing use in electronics and transformer cores, increasing adoption in medical devices and precision components, and expanding applications in automotive, aerospace, and renewable energy industries.

By Type Insights

The metal–metalloid segment is the dominant segment in the metallic glasses market due to its broad industrial applicability and well-established commercial use. These materials offer an optimal balance of mechanical strength, corrosion resistance, magnetic performance, and ease of processing, making them widely adopted across industrial manufacturing, automotive components, electronics, and energy-related applications. Their relatively mature production technologies and versatility across mass-market uses further strengthen their market position. In contrast, metal–metal hybrid glasses, although valued for their durability, optical clarity, and high-temperature resistance, are primarily used in specialized and high-end applications such as advanced optics and imaging systems, which limits their overall market penetration.

By Form Insights

The ribbons segment is the dominant form in the metallic glasses market due to its widespread use and strong performance advantages in magnetic applications. Ribbons offer exceptional soft magnetic properties, low core loss, and high efficiency, making them highly suitable for transformers, inductors, and magnetic sensors used across power, electronics, and energy industries. Their proven reliability, scalability in manufacturing, and cost-effective production further support their dominance. While wires, powders, and sheets are gaining adoption in emerging areas such as MEMS, biomedical devices, additive manufacturing, and structural shielding, these applications remain more specialized. As a result, ribbons continue to lead the market owing to their broad industrial acceptance and established demand base.

By Material Composition Insights

The iron-based segment is the dominant material composition in the metallic glasses market due to its extensive use across industrial and electrical applications. Iron-based metallic glasses offer excellent soft magnetic properties, high permeability, low energy loss, and strong corrosion resistance, making them highly suitable for transformers, motors, inductors, and power distribution systems. Their relatively lower material cost, ease of large-scale manufacturing, and proven performance in energy-efficient applications further reinforce their market leadership. While zirconium-, titanium-, and copper-based metallic glasses are gaining traction in medical, aerospace, and high-performance electronics, and lightweight magnesium- and aluminium-based variants are expanding in automotive and aerospace sectors, these remain more application-specific

By Manufacturing Process Insights

The extremely rapid cooling segment is the dominant manufacturing process in the metallic glasses market due to its effectiveness, reliability, and widespread industrial adoption. This process is the most established method for producing metallic glasses as it efficiently prevents atomic crystallization, enabling the formation of uniform amorphous structures with consistent mechanical and magnetic properties. Its scalability, cost efficiency, and compatibility with mass production make it highly suitable for industrial, automotive, and electrical applications. While physical vapor deposition and ion irradiation are increasingly adopted for precision thin films, coatings, and advanced electronics, and solid-state reactions are explored for specialized compositions, these methods remain more niche. Consequently, extremely rapid cooling continues to lead the market owing to its proven performance and broad applicability across industries.

Regional Insights

The United States represents a dominant market for metallic glasses, driven by strong demand from defence, aerospace, and advanced electronics sectors. Metallic glass technology aligns well with national requirements for high-performance, durable, and precision materials, encouraging adoption across mission-critical applications. Close collaboration between defence contractors, manufacturers, and research institutions accelerates innovation, alloy development, and commercialization. Additionally, the region benefits from expanding energy infrastructure, where amorphous metals are widely used in efficient transformer cores, alongside growing investments in clean energy, modern automotive manufacturing, healthcare technologies, and industrial automation.

Market Competitive Landscape

The metallic glasses market features a competitive landscape led by specialized material innovators and regional manufacturers focused on high-performance amorphous alloys. Key players differentiate through proprietary bulk metallic glass formulations, advanced processing capabilities, and application-specific solutions across electronics, aerospace, medical, and energy sectors. Market leaders emphasize near-net-shape molding, magnetic performance, and precision manufacturing, while Asian suppliers strengthen competitiveness through large-scale production and cost efficiency. European companies focus on customized, high-precision components for premium applications. Strong collaboration with research institutions, continuous alloy innovation, and growing adoption of injection molding and additive manufacturing technologies remain central competitive strategies shaping market positioning and long-term growth.

Recent Developments:

• In June 2024, Heraeus Holding enhanced its iridium recovery operations by acquiring McCol Metals, allowing the company to broaden its extraction of iridium from spent mixed metal oxide electrodes in Canada.

• In October 2023, EPSON ATMIX Corporation commissioned a sustainable metal refinery involving a 5.5-billion-yen investment in plant and equipment to recycle waste metals into raw materials for metal powder production. The project, part of the Seiko Epson Group, is located at Lot No. 16 in the Hachinohe Kita Inter Industrial Park, on land acquired by ATMIX through an agreement with Hachinohe City in July 2022.

• In February 2022, BASF and Heraeus formed a joint venture, BASF HERAEUS Metal Resource Co., Ltd, with each company holding a 50% stake, to recover valuable metals from used automotive catalysts. The venture is headquartered in Pinghu, China.

Scope of the report:

Report Metric Details

Market size available for the years 2021-2034

Base year considered 2024

Forecast Period 2025-2034

Segments Covered By Type, By Form, By Material Composition, By Manufacturing Process

Regions Covered North America, Latin America, Asia-Pacific, Europe, and Middle East & Africa

Companies Covered Amorphology Inc., Antai Technology Co., Ltd., EPSON ATMIX Corporation, Exmet AB, Glassimetal Technology, Heraeus Holding, Hitachi Metals Ltd., Liquidmetal Technologies Inc., Materion Corporation, PrometalTech, PX Group SA, Qingdao Yunlu Advanced Materials Technology Co., Ltd., RS Alloys, Usha Amorphous Metals Limited

Key Topics Covered in the Report

• Global Metallic Glasses Market Size (FY’2021-FY’2034)

• Overview of Global Metallic Glasses Market

• Segmentation of Global Metallic Glasses Market by Type (Metal-metal metallic glasses, Metal-metalloid metallic glasses)

• Segmentation of Global Metallic Glasses Market by Form (Ribbons, Wires, Powders, Sheets, and Others)

• Segmentation of Global Metallic Glasses Market by Material Composition (Iron-based, Zirconium-based, Titanium-based, Copper-based, Palladium-based, Magnesium-based, Aluminium-based, and other compositions)

• Segmentation of Global Metallic Glasses Market by Manufacturing Process (Extremely rapid cooling, Physical vapor deposition, Solid-state reaction, Ion irradiation, and Others)

• Statistical Snap of Global Metallic Glasses Market

• Expansion Analysis of Global Metallic Glasses Market

• Problems and Obstacles in Global Metallic Glasses Market

• Competitive Landscape in the Global Metallic Glasses Market

• Details on Current Investment in Global Metallic Glasses Market

• Competitive Analysis of Global Metallic Glasses Market

• Prominent Players in the Global Metallic Glasses Market

• SWOT Analysis of Global Metallic Glasses Market

• Global Metallic Glasses Market Future Outlook and Projections (FY’2025-FY’2034)

• Recommendations from Analyst

Global Metallic Glasses Market Size- By Type, By Form, By Material Composition, By Manufacturing Process - Regional Outlook, Competitive Strategies and Segment Forecast to 2034

1. Introduction

1.1. Scope of the report

1.2. Market segment analysis

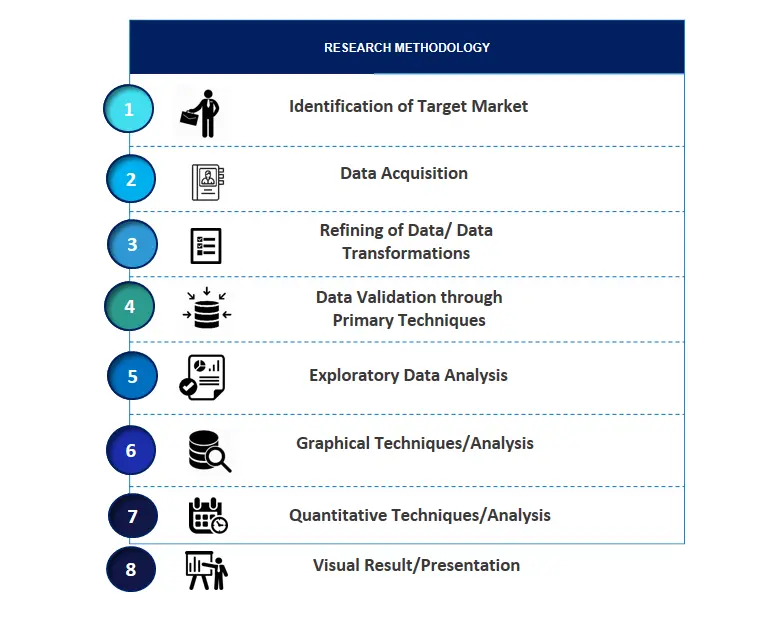

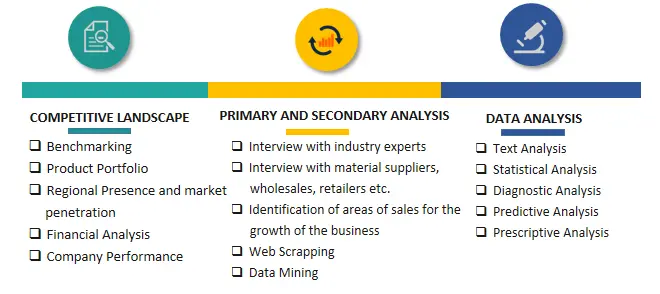

2. Research Methodology

2.1. Research data source

2.1.1. Secondary Data

2.1.2. Primary Data

2.1.3. SPER’s internal database

2.1.4. Premium insight from KOL’s

2.2. Market size estimation

2.2.1. Top-down and Bottom-up approach

2.3. Data triangulation

3. Executive Summary

4. Market Dynamics

4.1. Driver, Restraint, Opportunity and Challenges analysis

4.1.1. Drivers

4.1.2. Restraints

4.1.3. Opportunities

4.1.4. Challenges

5. Market variable and outlook

5.1. SWOT Analysis

5.1.1. Strengths

5.1.2. Weaknesses

5.1.3. Opportunities

5.1.4. Threats

5.2. PESTEL Analysis

5.2.1. Political Landscape

5.2.2. Economic Landscape

5.2.3. Social Landscape

5.2.4. Technological Landscape

5.2.5. Environmental Landscape

5.2.6. Legal Landscape

5.3. PORTER’s Five Forces

5.3.1. Bargaining power of suppliers

5.3.2. Bargaining power of buyers

5.3.3. Threat of Substitute

5.3.4. Threat of new entrant

5.3.5. Competitive rivalry

5.4. Heat Map Analysis

6. Competitive Landscape

6.1. Global Metallic Glasses Market Manufacturing Base Distribution, Sales Area, Product Type

6.2. Mergers & Acquisitions, Partnerships, Product Launch, and Collaboration in Global Metallic Glasses Market

7. Global Metallic Glasses Market, By Type (USD Million) 2021-2034

7.1. Metal-metal metallic glasses

7.2. Metal-metalloid metallic glasses

8. Global Metallic Glasses Market, By Form (USD Million) 2021-2034

8.1. Ribbons

8.2. Wires

8.3. Powders

8.4. Sheets

8.5. Others

9. Global Metallic Glasses Market, By Material Composition (USD Million) 2021-2034

9.1. Iron-based

9.2. Zirconium-based

9.3. Titanium-based

9.4. Copper-based

9.5. Palladium-based

9.6. Magnesium-based

9.7. Aluminium-based

9.8. Other compositions

10. Global Metallic Glasses Market, By Manufacturing Process (USD Million) 2021-2034

10.1. Extremely rapid cooling

10.2. Physical vapor deposition

10.3. Solid-state reaction

10.4. Ion irradiation

10.5. Others

11. Global Metallic Glasses Market, (USD Million) 2021-2034

11.1. Global Metallic Glasses Market Size and Market Share

12. Global Metallic Glasses Market, By Region, (USD Million) 2021-2034

12.1. Asia-Pacific

12.1.1. Australia

12.1.2. China

12.1.3. India

12.1.4. Japan

12.1.5. South Korea

12.1.6. Rest of Asia-Pacific

12.2. Europe

12.2.1. France

12.2.2. Germany

12.2.3. Italy

12.2.4. Spain

12.2.5. United Kingdom

12.2.6. Rest of Europe

12.3. Middle East and Africa

12.3.1. Kingdom of Saudi Arabia

12.3.2. United Arab Emirates

12.3.3. Qatar

12.3.4. South Africa

12.3.5. Egypt

12.3.6. Morocco

12.3.7. Nigeria

12.3.8. Rest of Middle-East and Africa

12.4. North America

12.4.1. Canada

12.4.2. Mexico

12.4.3. United States

12.5. Latin America

12.5.1. Argentina

12.5.2. Brazil

12.5.3. Rest of Latin America

13. Company Profile

13.1. Amorphology Inc.

13.1.1. Company details

13.1.2. Financial outlook

13.1.3. Product summary

13.1.4. Recent developments

13.2. Antai Technology Co., Ltd.

13.2.1. Company details

13.2.2. Financial outlook

13.2.3. Product summary

13.2.4. Recent developments

13.3. EPSON ATMIX Corporation

13.3.1. Company details

13.3.2. Financial outlook

13.3.3. Product summary

13.3.4. Recent developments

13.4. Exmet AB

13.4.1. Company details

13.4.2. Financial outlook

13.4.3. Product summary

13.4.4. Recent developments

13.5. Glassimetal Technology

13.5.1. Company details

13.5.2. Financial outlook

13.5.3. Product summary

13.5.4. Recent developments

13.6. Heraeus Holding

13.6.1. Company details

13.6.2. Financial outlook

13.6.3. Product summary

13.6.4. Recent developments

13.7. Hitachi Metals Ltd.

13.7.1. Company details

13.7.2. Financial outlook

13.7.3. Product summary

13.7.4. Recent developments

13.8. Liquidmetal Technologies Inc.

13.8.1. Company details

13.8.2. Financial outlook

13.8.3. Product summary

13.8.4. Recent developments

13.9. Materion Corporation

13.9.1. Company details

13.9.2. Financial outlook

13.9.3. Product summary

13.9.4. Recent developments

13.10. PrometalTech

13.10.1. Company details

13.10.2. Financial outlook

13.10.3. Product summary

13.10.4. Recent developments

13.11. PX Group SA

13.11.1. Company details

13.11.2. Financial outlook

13.11.3. Product summary

13.11.4. Recent developments

13.12. Qingdao Yunlu Advanced Materials Technology Co., Ltd.

13.12.1. Company details

13.12.2. Financial outlook

13.12.3. Product summary

13.12.4. Recent developments

13.13. RS Alloys

13.13.1. Company details

13.13.2. Financial outlook

13.13.3. Product summary

13.13.4. Recent developments

13.14. Others

14. Conclusion

15. List of Abbreviations

16. Reference Links